Category: Waterjet Technology

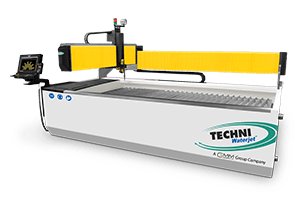

Cutting Glass With A Waterjet Cutter

Waterjet Glass Cutting | Can A Water Jet Cut Glass? Glass is the foundation for decor, from art to architecture. Specialist glass-cutting techniques are essential for such applications. Glass cutting is not as simple as it may sound. For one thing, glass is a delicate...

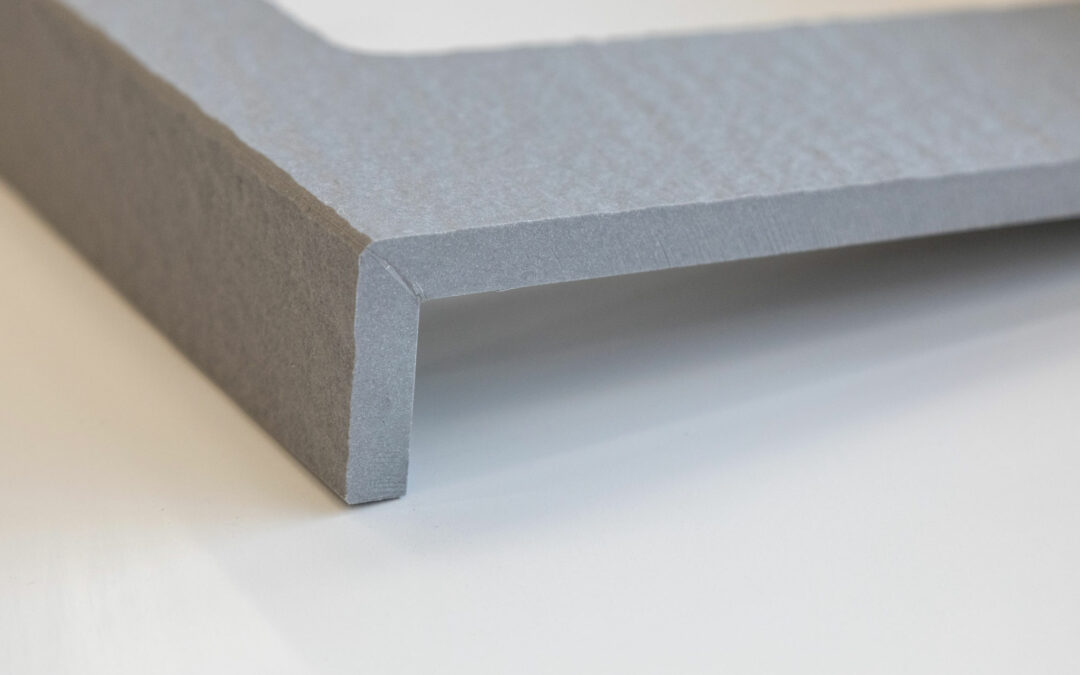

Cutting Stone With Water Jet Cutter

Natural stones are the first choice when anyone wants a material that is luxurious and durable at the same time. Among stones, there are many different materials, such as granite, marble, limestone, slate, and more. Stone cutting is required to make it usable for any...

Cutting Granite using a Waterjet Cutter

Granite is the foundation stone of decor in the modern world. From granite countertops in kitchens to entire monuments, granite has extensive applications due to its physical properties and appearance. The hardness of granite makes it challenging to work with. For...

Cutting Aluminum with a Water Jet Cutter

Aluminum is among the most common metals used in manufacturing industries. It undergoes many fabrication processes to make it suitable for different applications. One such process is cutting aluminum sheets and other components. For this purpose alone, many technology...

Waterjet Tile Cutting

Waterjet cutting is by far the best development in industrial cutting technology. From cutting stone to softer materials, a high-power water jet cutting head nozzle can cut through virtually anything regardless of the thickness. Benefits such as quality, precision,...

5-Axis Waterjet Cutting: What You Need to Know About Techni 5-Axis Waterjet Cutters

When waterjet cutting technology was developed, its use was limited to cutting soft materials such as paper and rubber. But water jet cutting soon found success, as it cut materials with superior results compared to many alternative cutting methods. No one might have...

Underwater Water Jet Cutting Technology

We have told you multiple times, in various articles, about the different materials that you can cut with a waterjet cutter. However, besides the wide range of materials, there are also many different ways in which you can cut. For instance, did you know you can cut...

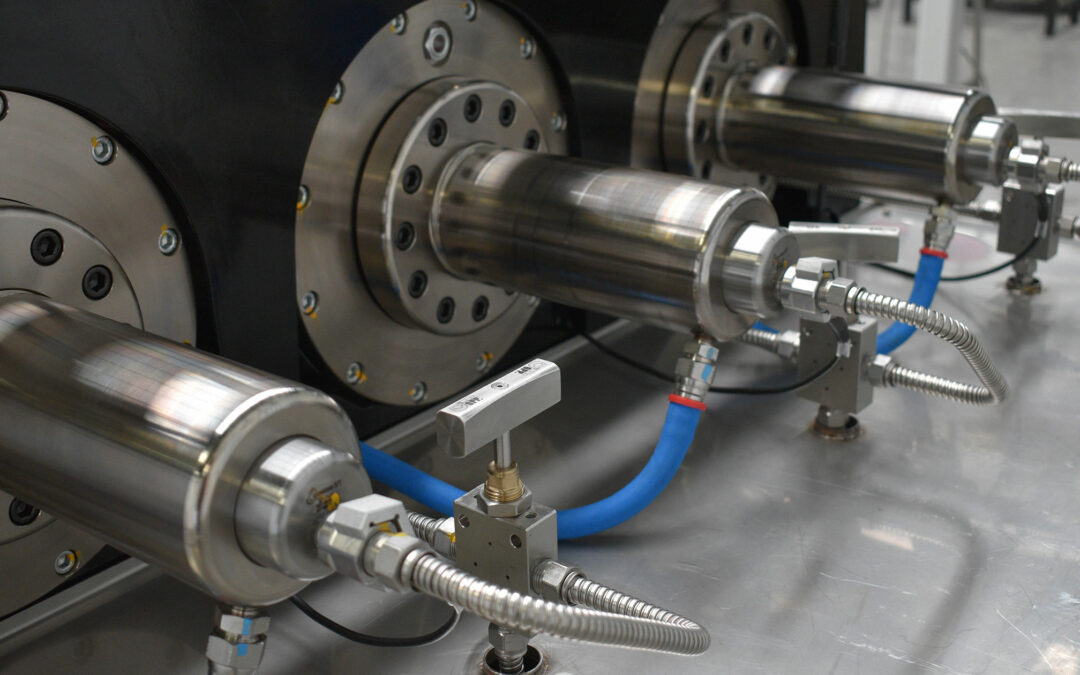

How to Choose a Water Jet Pump

Almost all industrial projects typically require the use of pressurized water in one way or the other. From cutting material to cleaning purposes , a high-velocity waterjet system finds its application in all metalworking, woodworking, mining, and other areas....

Water Jet Technology for Cutting Metals

When we talk about industrial projects, steel is one of the most commonly used harder materials. Workshops typically process steel sheets and blocks by cutting and shaping them to form smaller metal parts. There are many cutting process options, such as EDM, plasma,...

Is Water Jet Cutting Wood Possible?

There is hardly any technology as reliable as high-pressure waterjet cutting when talking about industrial cutting machines. We originally posted an article about the benefits of waterjet cutting and how it performs better than any other cutting alternatives. In this...